E: export@newstarchina.com

P: +86-595-2228 9926

F: +86-595-2228 7926

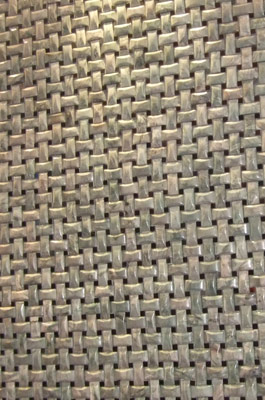

Mosaic has a long history of architectural applications. Mosaic ideals and ancient mosaic designs can be traced back many centuries, representing by Italian mosaic, roman mosaic and Greek mosaic crafts from the hands of famous mosaic artists .Natural stone mosaics like marble mosaic emerged as a key member of modern mosaic group in recent decades, making the mosaic idea even brighter. A set of marble mosaic in proper designs has vast applications. More and more marble mosaic floors, marble mosaic ceilings,marble mosaic walls and outdoor marble mosaic paving are seen in modern buildings. Partnering with the leading marble mosaic manufacturer in China,crafts and imports hundreds beautiful designs of marble mosaic,marble mosaic tiles, in the form of marble mosaic pattern,marble mosaic medallion,marble mosaic tile,marble mosaic art piece and marble mosaic border, mounted on sheets ready for installations. Newstar stone marble mosaics are completely customizable in dimension, chip color, chip size and chip shape. Five basic stone mosaics are: mosaic pattern, made of stone chips in different shapes and sizes;marble mosaic tile, assembled with uniform square chips for simple decoration;marble mosaic medallion, resembling inlayed stone medallion but in the form of marble mosaic; mosaic border, in stripe designs for wall and floor bordering applications; and marble mosaic art. China Newstar stone mosaics are assembled by the hands of well-trained craftsman, based on drawings of professional designs.

Mosaic has a long history of architectural applications. Mosaic ideals and ancient mosaic designs can be traced back many centuries, representing by Italian mosaic, roman mosaic and Greek mosaic crafts from the hands of famous mosaic artists .Natural stone mosaics like marble mosaic emerged as a key member of modern mosaic group in recent decades, making the mosaic idea even brighter. A set of marble mosaic in proper designs has vast applications. More and more marble mosaic floors, marble mosaic ceilings,marble mosaic walls and outdoor marble mosaic paving are seen in modern buildings. Partnering with the leading marble mosaic manufacturer in China,crafts and imports hundreds beautiful designs of marble mosaic,marble mosaic tiles, in the form of marble mosaic pattern,marble mosaic medallion,marble mosaic tile,marble mosaic art piece and marble mosaic border, mounted on sheets ready for installations. Newstar stone marble mosaics are completely customizable in dimension, chip color, chip size and chip shape. Five basic stone mosaics are: mosaic pattern, made of stone chips in different shapes and sizes;marble mosaic tile, assembled with uniform square chips for simple decoration;marble mosaic medallion, resembling inlayed stone medallion but in the form of marble mosaic; mosaic border, in stripe designs for wall and floor bordering applications; and marble mosaic art. China Newstar stone mosaics are assembled by the hands of well-trained craftsman, based on drawings of professional designs.